Calcium carbide is more than a chemical—it's a powerhouse of energy driving progress across industries.

Consumer Products

Acetylene derivatives are found in everyday consumer products including hairspray, cosmetics, medications, lotions and toothpaste.

Acetylene intermediates play a crucial role in the production of fibers, rubbers, solvents and refrigerants.

Industrial Gas

Industrial Processing

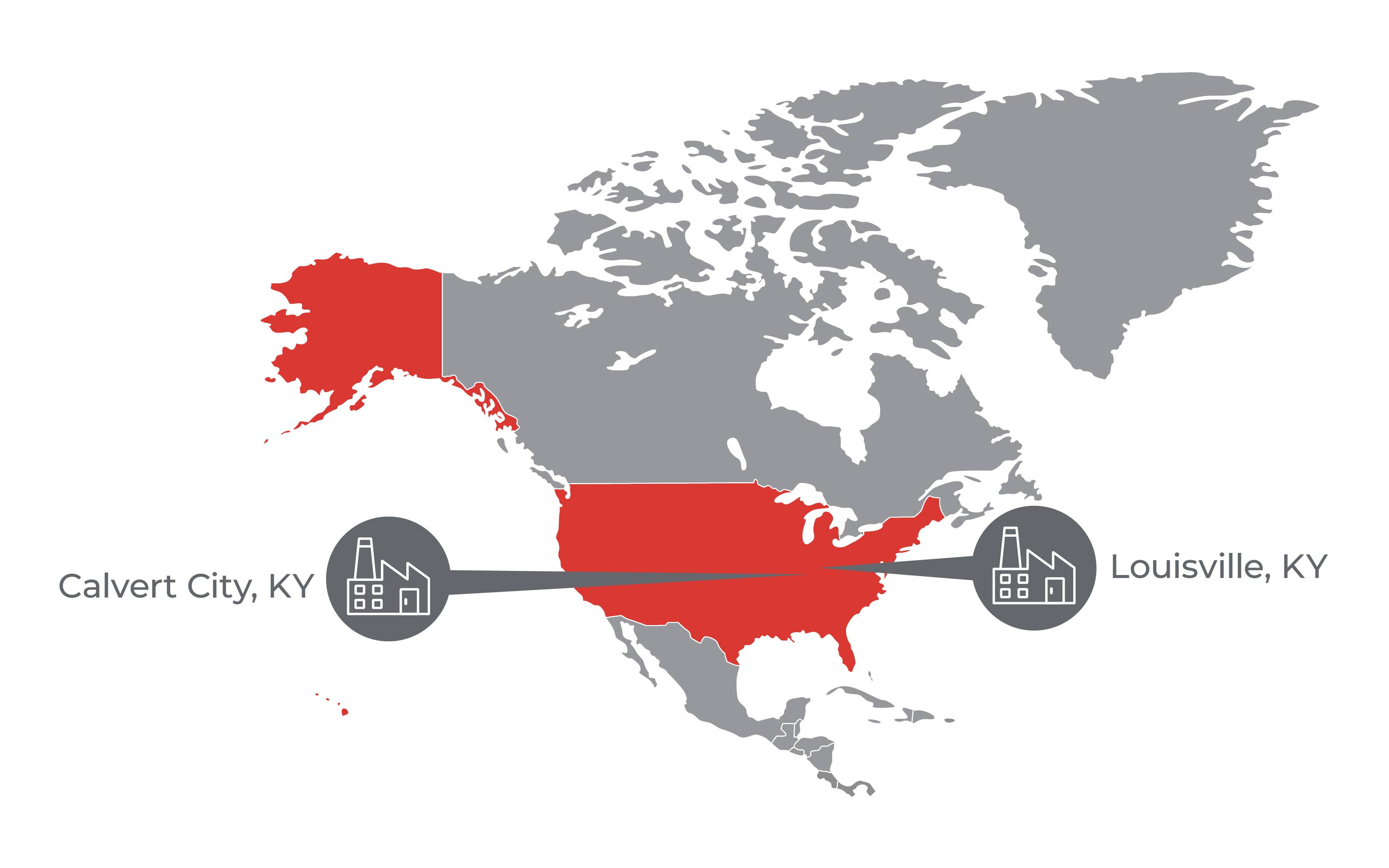

Deeply rooted in American history and the invention of the electric arc furnace.

North America's Largest Submerged Arc Furnace

The Carbide Industries story began in 1892, J.T. Morehead, T.L. Wilson, and J.C. King set out to refine aluminum—a metal more valuable than gold at the time. Using a new process that involved heating ore, lime, and coke in the newly developed electric arc furnace (EAF), they aimed to revolutionize aluminum production.

Although their process failed to refine aluminum, it gave rise to a groundbreaking discovery: the discarded materials became the foundation of an entirely new industry, producing one of the most important chemicals of the 20th century—calcium carbide.

Using the same basic process discovered in the 1890’s, modern calcium carbide involves heating a mixture of coke and lime at extremely high temperatures in an electric arc furnace (EAF).

During World War II rubber was in high demand. To meet this critical need, the US government, academia and industrial laboratories came together to develop a synthetic rubber to meet the demand. A key ingredient in this effort, butadiene, was derived from acetylene gas generated from calcium carbide. The plant used during World War II to generate acetylene gas would later become Carbide Industries carrying forward a legacy of innovation and industrial progress.

Carbide Industries’ story of success has resulted in an ultra-efficient submerged arc furnace (SAF) is the largest of its kind in North America. Designed for maximum efficiency, the SAF operates with the electrodes fully submerged in the charge of coke and lime, optimizing the production process and supplying the furnace with the energy efficiency required to achieve the nearly 4,000º F temperatures needed to manufacture carbide – 1,000º hotter than a steel furnace.

Molten carbide is continuously extracted from the furnace and cooled in special molds. After cooling, the carbide is crushed and screened to meet precise sizing requirements, ensuring a high-quality product is ready for use in a variety of applications.

Delivery

Acetylene can be delivered via pipeline direct to a manufacturing facility or through large national distributors of industrial gases.

Your sales representative will work with you to find the right solution for your location.

Calcium hydroxide is available in both dry and slurry forms and is shipped directly in a can, drum or in bulk.

Safety & Technical Support

Contact your sales representative to learn about our safety training program for the safe handling, storage and use of our products.

Technical support is also available for acetylene generation and calcium hydroxide use.

Quality Control

An on-site laboratory and team of experts test our products before shipping. Time-tested procedures are in place to control our processes and to certify shipments. In addition, there are systems in place for handling any customer-found issues.

Outside testing firms, when necessary, can provide scanning electron microscopy, energy dispersive x-ray analysis, gas chromatography and infrared spectroscopy for those times when closer investigation is needed.