Engineering that empower producers.

Opta Group delivers mission-critical metallurgical solutions that enhance efficiency, reliability and sustainability across the globe. Through custom-engineered additives, advanced application systems and 24/7 technical expertise, we partner with producers to achieve higher yields, lower energy consumption and consistent, high-quality results, all while reducing environmental impact and advancing cleaner, more sustainable steelmaking.

At Opta Group, we don’t just supply materials, we integrate solutions directly into our customers’ operations. Our hands-on, collaborative approach ensures that every product, process and service we deliver is aligned with our customers’ goals for efficiency, reliability and performance. With an embedded presence at production sites, we drive measurable operational impact by improving process stability, enhancing quality and achieving greater cost savings across every stage of the metallurgical process.

End-to-End Partnership

Our global footprint allows us to deliver consistent, standardized service and maintain deep, long-term partnerships. Whether it’s real-time process support or proactive optimization, our teams are there where and when they’re needed most.

Every partnership is backed by trusted expertise and a global network of highly skilled metallurgists, engineers and field technicians who work side by side with producers to solve critical challenges and continuously advance performance.

---- Learn more about Metallurgical Consulting.

Our Brands

Our Solutions

Iron & Hot Metal Desulfurization

We custom-engineer magnesium-based, calcium carbide-based and fluidized lime-based carrier reagents, along with blended solutions designed to remove impurities and enhance product quality. These specialized formulations help our customers achieve cleaner melts, higher yields and more consistent end products across a wide range of metal and steelmaking applications.

Custom Designed Fluxes

From providing insulation and absorbing inclusions to stabilizing flow, our fluxes play a critical role in the processing of molten metals, steel, aluminum, copper and other non-ferrous metals. Our solutions are designed to adjust slag viscosity and melting characteristics, ensuring proper flow and more efficient impurity removal from molten metal. This optimized slag flow minimizes build-up on furnace linings and equipment, creating a more stable operating environment and extending refractory life.

Advanced Deoxidation Solutions

Whether at the tap, in the ladle or during refining, our advanced deoxidation solutions effectively remove excess oxygen to prevent oxide inclusions, ensure predictable alloy behavior, maximize alloy recovery and extend ladle life.

Technical Services

Through continuous innovation and close collaboration with our customers, we develop purpose-built solutions that extend the boundaries of process efficiency, product quality and sustainability.

Cored Wire Treatments

Our cored wire consists of powdered minerals, metals, ferroalloys and master alloys tightly encased in a metallic sheath, offering both technical and economic advantages. It is especially effective when handling reactive metals, high-cost additives or any element that requires precise measurement.

Application Equipment

The equipment used in treating liquid metal is just as important as the chemical elements and compounds being added. Opta Group offers a wide range of application equipment that can be customized to meet the specific needs and requirements of each facility.

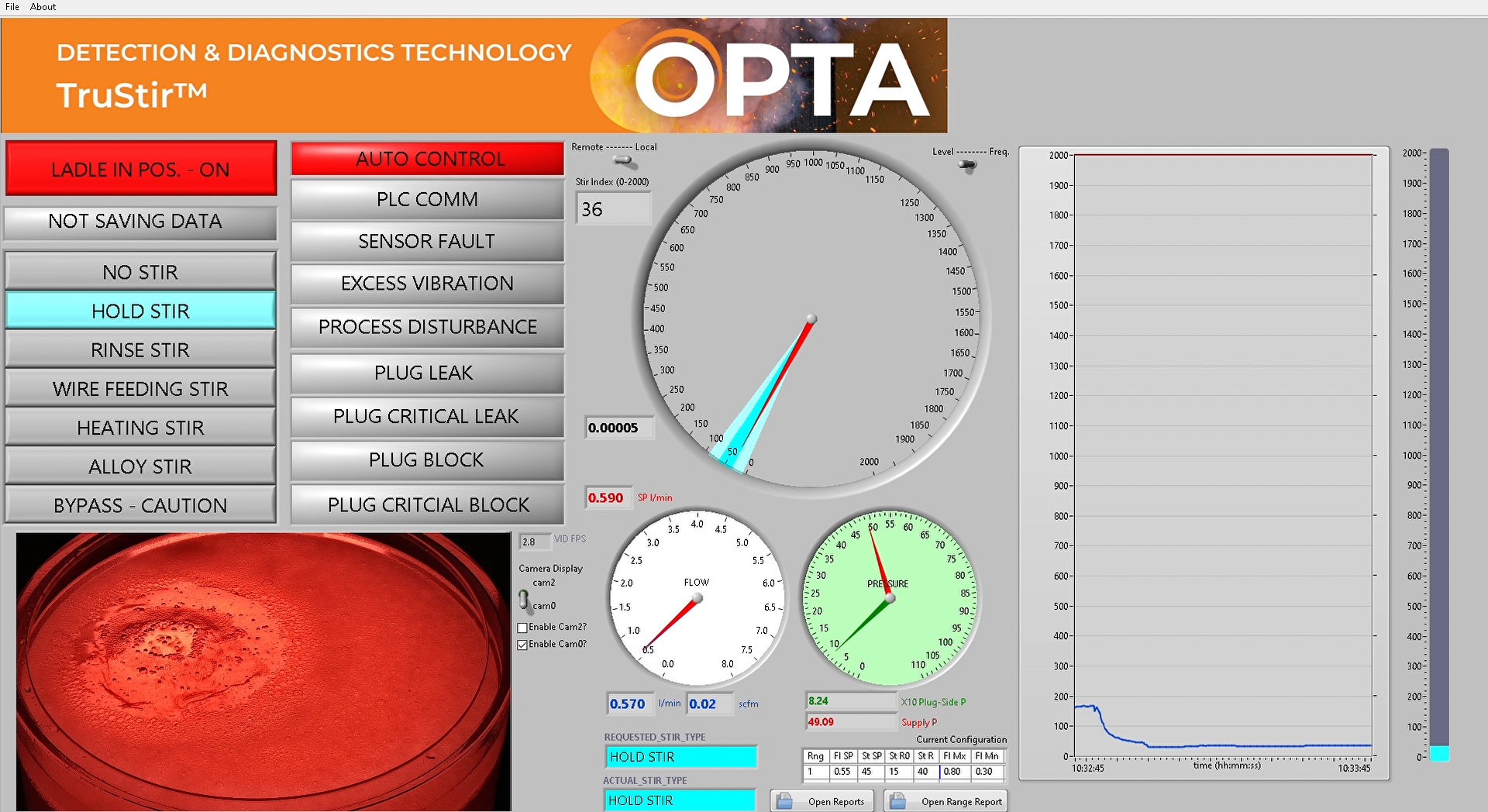

Detection & Optimization Technology

When existing tools fall short, our engineers design and build custom equipment that integrates seamlessly with our performance additives to deliver precise, reliable and measurable results.