OPTA offers a diverse product portfolio of molten solutions serving the iron, steelmaking, foundry, aluminum and copper industries. Our unparalleled metallurgical expertise has enabled us to become the world leader in iron desulfurization, slag conditioners and tundish fluxes.

From tap to cast, we have the products and expertise to be your one source for all metallurgical needs.

Quality Products. Exceptional Service.

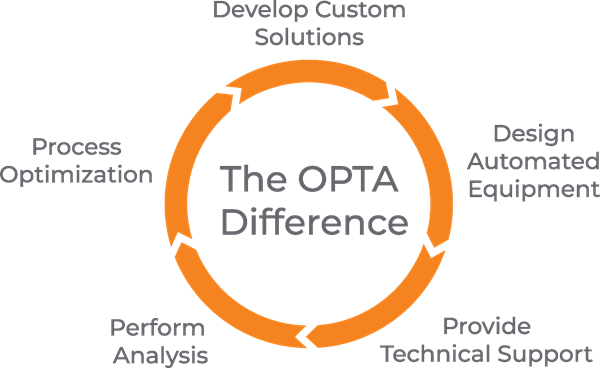

Innovation and value are the cornerstones of our product approach. As an industry leader in research and development, OPTA anticipates evolving market needs.

We custom-engineer a wide range of solutions for steel making and foundries. When it comes to service, we’re much more than just a supplier. We are a trusted partner working alongside you to achieve optimal results.

Opta specializes in bulk and pre-packaged fluxes and insulators for the metallurgical industries.

The chemistry and packaging of OPTA products are completely customizable and often specifically designed for each customer by technical experts. Many producers try to blend their own fluxes and bucket fluxes into their furnaces with varying application rates, which can result in poor performance, low recovery, and increased consumption/cost. Opta’s pre-packaged or bulk fluxes deliver consistent material chemistries and application rates, which can improve performance, decrease cost, and reduce refractory wear.

- Stop hand-blending your own formulas.

- Stop sacrificing refractory performance for aluminum quality.

- Decrease your flux consumption by choosing fluxes specifically designed to optimize aluminum quality and refractory performance.

Products

We deliver proprietary multi-purpose additives and customized solutions that are formulated to meet the unique needs of each customer, removing impurities, improving efficiency and increasing quality.

Performance

We thoughtfully design, engineer and install customized equipment, hardware and software for the application of our products to ensure peak performance, minimize waste and improve processing times.

People

We have over 100 field technicians and sales representatives who continue to work with our customers after delivery and installation meeting service needs, training and operating equipment, analyzing performance and consulting with customers to improve their formulations.

Proximity

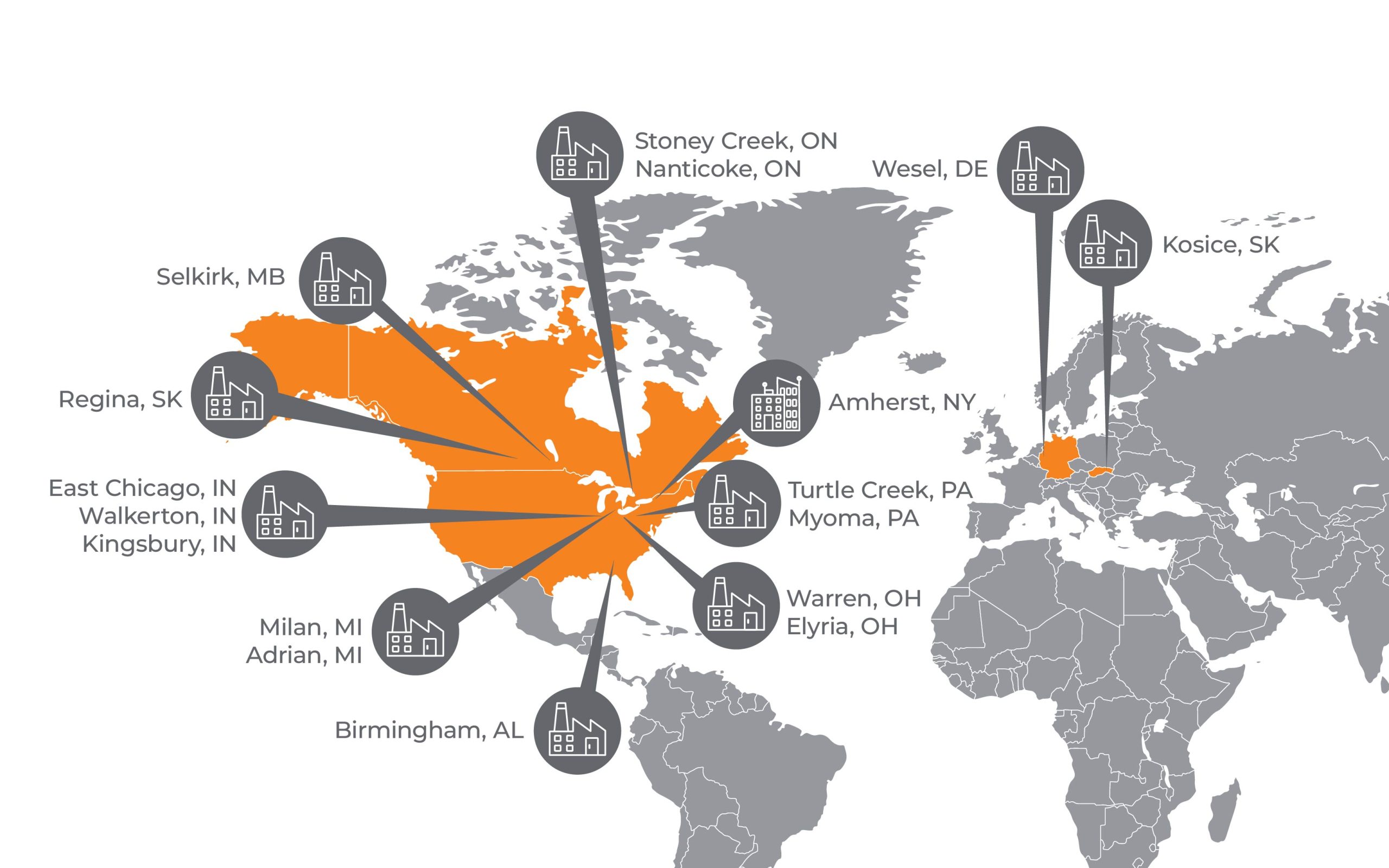

Our facilities are on average less than 2 hours from our customers or co-located within our customers’ location, enabling us to provide service and support quickly, minimizing downtime and maximizing production.

Iron & Hot Metal Desulfurization

- Magnesium-based reagents

- Calcium Carbide-based reagents

- Fluidized lime-based reagents

- Custom blended

Custom Designed Fluxes

- Briquettes

- Calcium Carbide

- Insulators

- Slag Conditioners

- Tundish Powders

Equipment & Technology

- Desulfurization Stations

- Injection Systems

- SlagTracker System

- SlagView System

- TruStir™ System

Service & Support

- Customer Service

- Field Service

- Process Engineering

- Technical Service